As the world embraces the electric vehicle (EV) revolution, the spotlight is on a critical component that lies at the heart of this transformation: battery copper foil. This essential material in lithium-ion batteries not only impacts the efficiency and longevity of EV batteries but also influences production costs and environmental sustainability. This article explores the groundbreaking advancements in copper foil production that are redefining the EV battery industry.

The Vital Role of Copper Foil in EV Batteries

Copper foil acts as the current collector for the anode in lithium-ion batteries, and its properties are crucial for optimal battery performance:

- High Electrical Conductivity: Copper’s excellent conductivity ensures efficient electron flow, enhancing battery power and charging speed.

- Mechanical Strength and Flexibility: Copper foil withstands the rigors of manufacturing processes and the stresses of battery operation, contributing to battery durability.

- Thermal Stability: The ability to maintain performance under varying temperatures is essential for reliable battery operation in diverse climates.

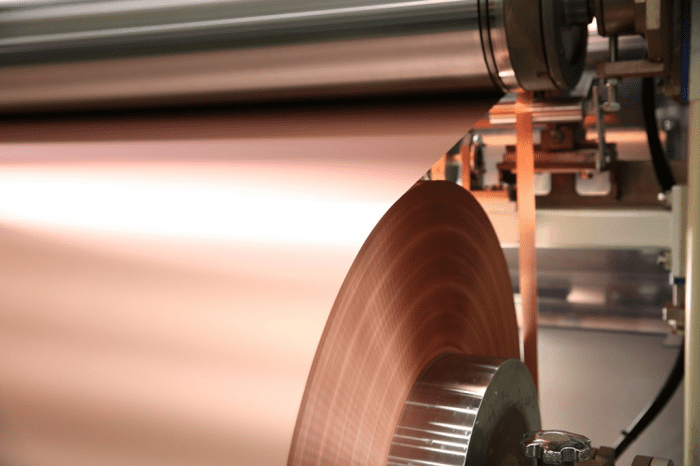

Pushing the Boundaries: Cutting-Edge Developments in Copper Foil Technology

Precision Thickness Control

Advancements in rolling technology have enabled the production of copper foils with unparalleled thickness precision. This breakthrough has significant implications for battery performance:

- Increased Energy Density: Thinner copper foils allow for more space to accommodate active materials, resulting in higher battery capacity and longer driving ranges.

- Improved Battery Lifespan: Uniform thickness distribution ensures consistent performance throughout the battery’s life, reducing the risk of premature degradation.

State-of-the-Art Surface Treatment

Innovative surface engineering techniques, such as advanced electroplating and texturing methods, have revolutionized the adhesion between copper foil and anode materials. These treatments offer several benefits:

- Enhanced Efficiency: Improved contact and electron flow between the copper foil and active materials lead to higher battery efficiency and faster charging.

- Reduced Degradation: Stronger adhesion minimizes the detachment of active materials from the copper foil, mitigating capacity loss over time.

Sustainable Manufacturing Processes

Leading copper foil manufacturers are adopting eco-friendly production methods to minimize the environmental impact of battery production:

- Recycling Initiatives: The implementation of closed-loop recycling systems and the use of recycled copper reduce waste and conserve natural resources.

- Energy-Efficient Processes: Optimization of energy consumption during copper foil production, through advanced process control and heat recovery systems, reduces the carbon footprint of battery manufacturing.

The Future of Battery Copper Foil: Driving Innovation and Sustainability

As the demand for electric vehicles continues to soar, the need for high-quality, sustainable battery copper foil becomes increasingly critical. Ongoing research and investment in this field are vital for:

- Driving Continuous Innovation: Collaborations between copper foil manufacturers, battery makers, and research institutions are essential to keep pace with evolving battery technologies and market demands.

- Promoting Environmental Sustainability: Balancing performance enhancements with eco-friendly practices is crucial for ensuring the long-term sustainability of the EV battery industry.

Conclusion: Copper Foil Innovations Powering the Electric Vehicle Revolution

The advancements in copper foil production, from precision thickness control to sustainable manufacturing processes, are not mere incremental improvements; they are transformative innovations that are reshaping the EV battery landscape. As we navigate the path towards a cleaner, greener future, the continued development of cutting-edge copper foil technologies will be instrumental in powering the electric vehicle revolution.